The pump design consists of two pumping chambers with each one being alternately refilled and pressurized. During operation, the pumping fluid is pneumatically driven from the main propellant tank into one of the two pumping chambers. The fluid is pressurized to a desired exit pressure via a tank of very high pressurized gas. Once the desired pressure level is achieved, the fluid is dispensed from the entire pump chamber unit into the desired output.

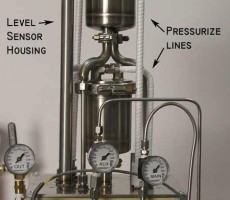

The pump is designed so that the time required to vent, refill and pressurize one pumping chamber is less than the time to dispense a given quantity of fuel from the other. The pump controls are set up so that when the level in one side gets low, the other side is pressurized. After flow is established from both chambers, the low side is vented and refilled quickly. This results in steady flow and pressure through the pump unit. Sensors in the pump unit detect when one pump chamber is almost empty, and trigger a series of valve actions to switch dispensing to the other pump chamber.